Your margins are shrinking because your delivery vehicles are stuck in traffic or circling for parking. Fleet managers face a daily battle against congestion, rising fuel costs, and stricter city regulations.

A cargo tricycle is a purpose-built logistics tool designed to maximize drop density in urban centers, especially when using commercial-grade cargo tricycles engineered for daily fleet operations.Unlike vans, they utilize bike lanes and curb parking to bypass congestion. Unlike scooters, they offer stable, high-volume capacity (up to 300kg). They reduce cost-per-delivery by increasing speed and eliminating fuel expenses.

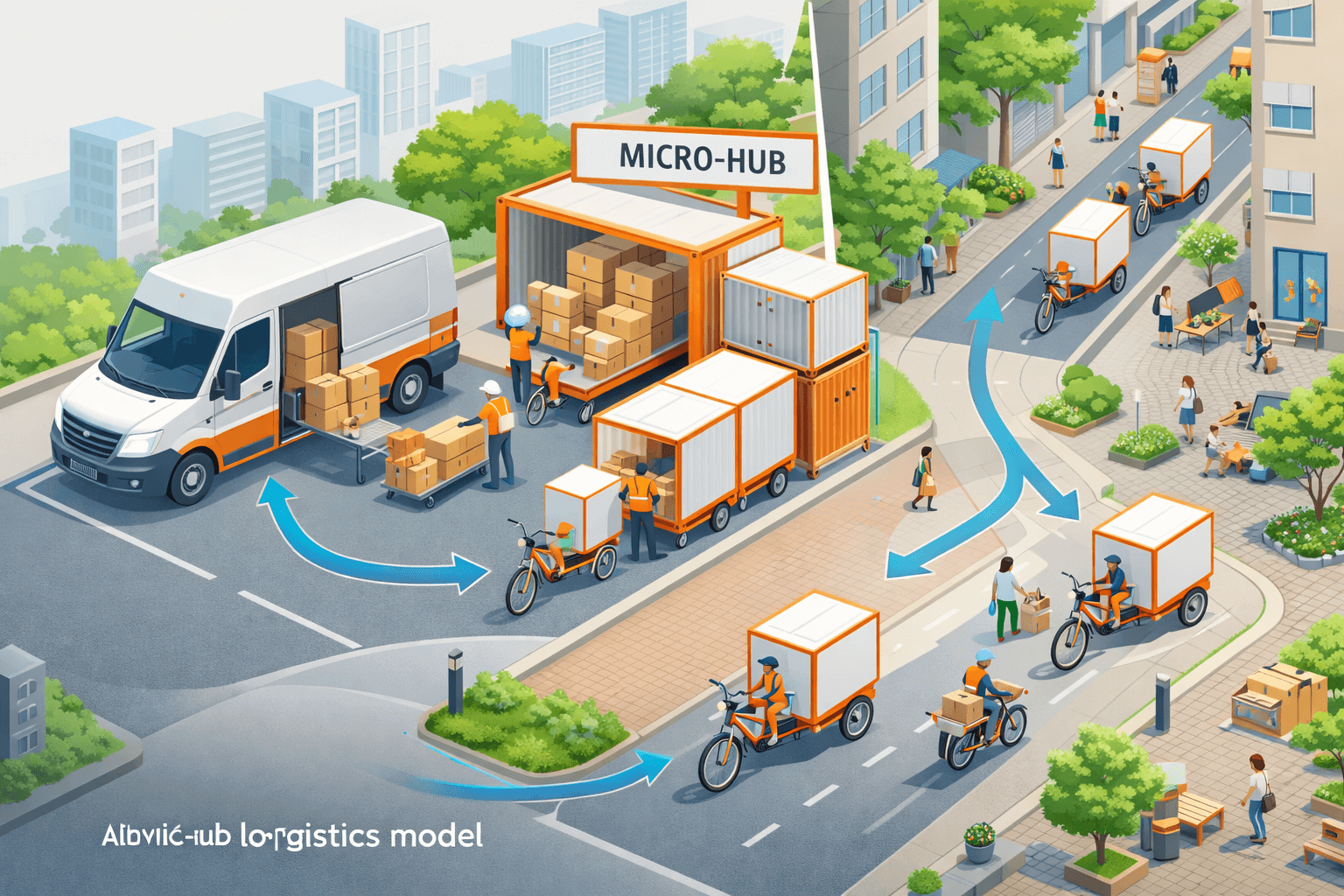

Deployed as a fleet, cargo tricycles support efficient last-mile delivery from urban micro-hubs to city centers and residential areas.

Many operators hesitate to change their fleet mix because they view tricycles as recreational items rather than industrial assets. However, when we look at the operational data regarding cost per stop and vehicle utilization, the argument for specialized vehicles becomes clear. Let’s examine why the traditional van-based model is failing in the city center.

Why Last-Mile Delivery Costs Keep Rising for Fleet Operators?

Sending a two-ton diesel van to deliver a two-kilogram package in a dense city center is an operational failure. You are paying for capacity you cannot use and time you cannot recover.

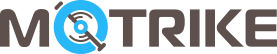

Delivery costs rise due to a combination of "stem mileage" inefficiencies and last-mile friction. Vans suffer from high fuel consumption in stop-start traffic, expensive parking fines, and downtime caused by limited loading zones. Furthermore, Low Emission Zones (LEZ) in cities like London, Berlin, or Paris force expensive fleet upgrades.

As traffic congestion worsens in dense cities, delivery vans face rising fuel and maintenance costs, highlighting the need for alternative last-mile delivery solutions1.

The core issue is not just the price of fuel; it is the mismatch between the vehicle and the environment. In fleet management, we track Total Cost of Ownership (TCO), but we often overlook "Total Cost of Operation" on a per-route basis. When a van driver spends 15 minutes finding a legal loading bay, that is 15 minutes of paid labor with zero productivity. If they park illegally to save time, the resulting fine wipes out the profit margin for that entire route.

We also face a maintenance crisis with traditional vehicles. Internal combustion engine vans are not designed for the grueling stop-and-go nature of door-to-door delivery. This leads to premature wear on brakes, starters, and transmissions. Even electric vans (EVs) struggle here; while they save on fuel, they are still large vehicles that get stuck in the same traffic jams as diesel trucks. They require large parking spaces and expensive charging infrastructure at the depot.

From my experience working with European clients, the hidden cost is workforce turnover. Driving a large van in a narrow, aggressive city center is stressful. Drivers burn out. By contrast, rising costs can be mitigated by moving to a vehicle class that is immune to congestion charges and parking restrictions. We must stop trying to force highway vehicles to work in pedestrian zones.

What a Cargo Tricycle Really Is — from a Fleet Management Perspective?

You should not view a cargo tricycle as a bicycle. You must view it as a light commercial vehicle (LCV)2 that happens to have pedals. This distinction is vital for your procurement strategy.

From a fleet perspective, a cargo tricycle is a non-licensed, zero-emission logistics asset3. It combines a payload capacity of 200kg to 300kg with the agility of a bicycle. It creates a new asset class that requires lower driver qualifications, allowing you to recruit from a much wider labor pool.

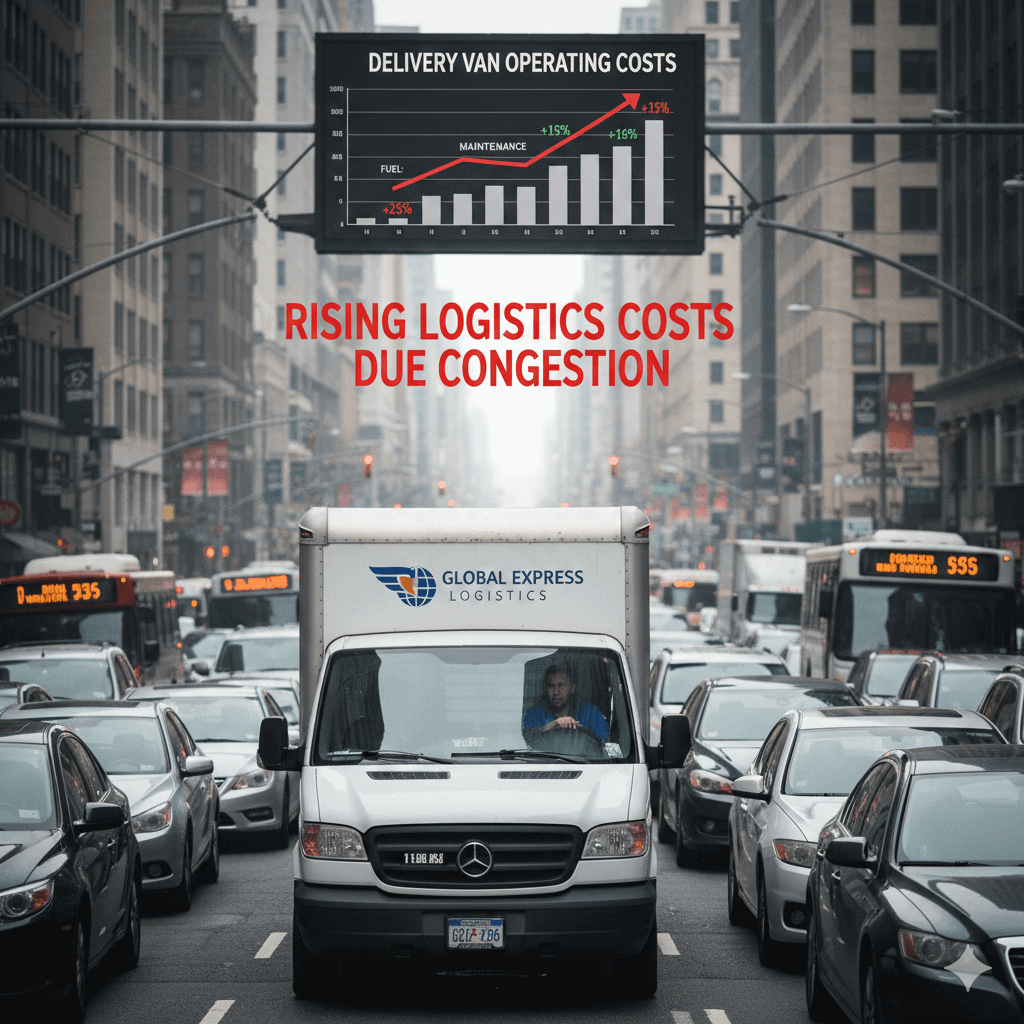

Each cargo tricycle frame is built and inspected in our workshop, allowing customization for payload, drivetrain, and commercial application requirements.

When I discuss this with fleet managers, I break the vehicle down into operational capabilities rather than cycling components. A commercial cargo tricycle is defined by its chassis stability, braking power, and cargo security. It is not a consumer bike with a box attached.

The frame is reinforced high-tensile steel designed to handle static and dynamic loads daily. The wheels are often motorcycle-grade to prevent buckling under weight. The electric assist (pedelec) system is torque-sensing, meaning it amplifies human effort to move heavy loads up gradients without burning out the motor.

Critically, for a manager, this vehicle is a "compliance tool." It is legally classified as a bicycle in most jurisdictions. This means:

- No License Required: You can hire young staff or students.

- No Registration/Road Tax: Immediate reduction in fixed overheads.

- Access All Areas: You can enter pedestrian zones, bike lanes, and parks where vans are physically or legally banned.

However, you must treat it like a truck during procurement. Does it have a differential for cornering stability? Is the box lockable and waterproof? Is the battery swappable for multi-shift operations? If you treat it like a toy, it will fail. If you treat it like a light truck, it will deliver value.

Cargo Tricycles vs Vans and Scooters: Cost, Utilization, and ROI Comparison?

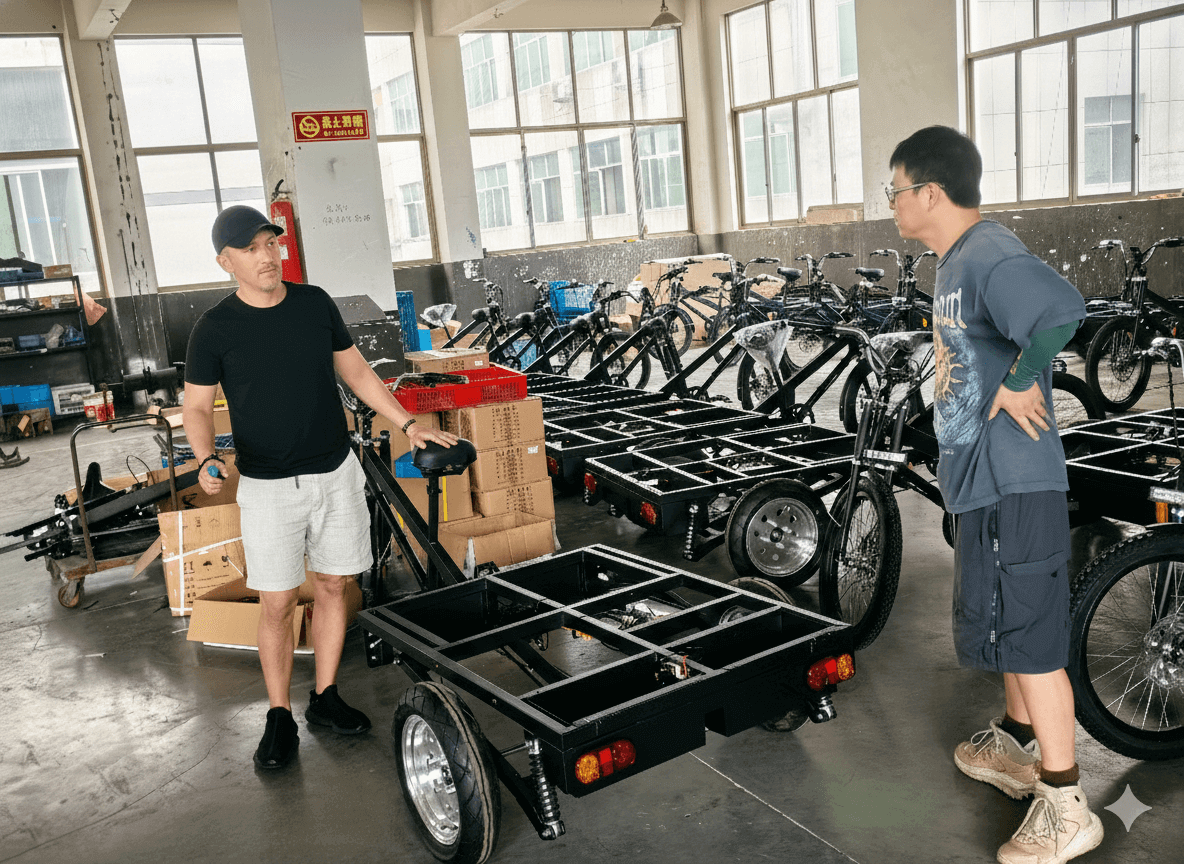

Data drives decisions. We need to compare these vehicles not on their purchase price, but on their ability to complete drops per hour and their cost per kilometer.

Vans offer high volume but low average speed and high operational costs. Scooters offer speed but negligible volume and safety risks. Cargo tricycles4 occupy the optimum middle ground: they handle 60% of typical urban van loads at 10% of the cost, often achieving higher average speeds in gridlock.

Cargo trikes deliver higher fleet ROI in dense urban areas by combining low operating costs with efficient last-mile delivery from micro-hubs.

Let us look at the trade-offs in a structured way. I often help clients build this exact matrix to justify the investment to their CFOs.

| Feature | Diesel/Electric Van | 2-Wheel Scooter | Commercial Cargo Trike |

|---|---|---|---|

| Payload | 800kg+ | <20kg | 200kg – 300kg |

| Parking | Difficult / Expensive | Easy | Easy / Curbside |

| Traffic Impact | High (Stuck) | Low (Filtering) | Low (Bike Lanes) |

| Driver License | Required | Required | Not Required |

| OpEx (Fuel/Maint) | High | Low | Very Low |

| Safety | High Driver Safety | High Rider Risk | Moderate/High Stability |

The ROI Calculation:

A van costs significantly more upfront and bleeds money daily in fuel, insurance, and depreciation. A scooter is cheap but limits you to food delivery or single envelopes; you cannot scale a logistics business on scooters alone.

The cargo tricycle ROI usually turns positive within 6 to 9 months. The savings come from two places. First, the fuel/energy cost is negligible. Charging a trike battery costs pennies compared to filling a tank. Second, and more importantly, is drop density.

In a city center, a van driver might manage 10 drops an hour because 40 minutes are spent driving or parking. A trike rider can often manage 15-20 drops an hour because they park immediately at the customer’s door. You are paying for delivery, not for sitting in traffic. That efficiency gain pays for the vehicle faster than the fuel savings.

Real-World Fleet Deployments in Logistics, Retail, and E-commerce?

You might worry that these vehicles are unproven. However, major logistics players and smart local businesses are already running successful operations using them right now.

Fleets deploy tricycles in "hub-and-spoke" models. Vans bring bulk goods to a micro-hub (a container or small depot), and tricycles perform the final 3km delivery. This is common in grocery delivery, parcel logistics, and even facility maintenance where technicians need to carry tools into car-free zones.

Large delivery vehicles consolidate parcels at a local micro-hub, while electric cargo tricycles complete last-mile deliveries in narrow city streets and residential areas.

I have observed three distinct deployment models that work effectively in the real world.

1. The Micro-Hub Parcel Model5:

This is the standard for companies like DHL or Amazon in dense cities. A large truck drops huge containers at a city-center parking lot or rented garage in the morning. A fleet of 5-10 cargo trikes then loads from this hub. The trikes do short loops, returning to reload multiple times a day. This keeps the big truck out of the narrow streets and maximizes the trikes’ uptime.

2. The High-Speed Grocery Model:

For companies promising "15-minute delivery," vans are too slow. Scooters cannot carry enough water packs or bulk items. Cargo trikes with insulated boxes are the standard here. They can carry 4-5 heavy orders at once, ensuring the rider is productive and not just driving back and forth for a single bag of chips.

3. Service and Maintenance Fleets:

This is an emerging sector. Plumbers, window cleaners, and facility managers are switching to trikes. They do not need to transport pallets; they need to transport toolboxes and spare parts. In cities with strict parking enforcement, a technician can park a trike on the sidewalk right in front of the building. This saves the technician 20 minutes of walking from a parking garage, directly increasing their billable hours.

How Fleet Managers Choose the Right Cargo Tricycle for Daily Operations?

If you buy a consumer-grade tricycle for commercial work, it will break in three weeks. That is why commercial cargo tricycles must be built and inspected for heavy-duty fleet use.You must select vehicles engineered for the abuse of daily logistics operations.

Choose vehicles based on durability and serviceability, not aesthetics. Key features to look for include: heavy-duty wheels with 12G spokes, differential gears for stability, hydraulic disc brakes for stopping power, and a mid-drive motor for torque. Ensure your supplier stocks spare parts locally to minimize downtime.

Each cargo tricycle undergoes hands-on inspection and adjustment during final assembly to ensure consistent performance and long-term reliability for commercial operations.

When I advise clients on selecting a unit, I tell them to look at the "failure points." In commercial use, a vehicle will be ridden over curbs, overloaded by drivers, and left out in the rain.

The Checklist for Decision Makers:

- The Motor: Do not use a hub motor for heavy loads. You need a Mid-Drive motor. It uses the bike’s gears to generate torque, which is essential for starting from a dead stop with a 200kg load.

- The Wheels: Look for motorcycle-grade rims or reinforced spokes. Standard bicycle wheels will buckle under lateral cornering forces when fully loaded.

- The Battery: Is it easily swappable? You cannot afford to have the vehicle plugged into a wall for 4 hours during the day. You need to swap the battery in 10 seconds and keep moving.

- After-Sales Support: This is the most critical factor. Machines break. When they do, does the vendor have the part on the shelf? Or do you have to wait two months for a shipment from overseas?

At Motrike, we learned this the hard way. We see many fleets fail because they bought the cheapest option. The "cheap" option becomes the most expensive option when it spends two weeks in the repair shop. You are buying "uptime," not just a metal frame. Verify the load rating and ask for references from other commercial users.

Conclusion

Cargo tricycles are not a universal replacement for vans, but they are the superior tool for the final urban mile. By right-sizing your fleet, you reduce overheads, avoid congestion, and significantly improve your service reliability.

-

Exploring this link will provide insights into innovative delivery methods that can reduce costs and improve efficiency. ↩

-

Understanding LCVs can enhance your procurement strategy and operational efficiency. ↩

-

Explore how zero-emission logistics can reduce costs and improve sustainability in your fleet. ↩

-

Explore how cargo tricycles optimize delivery efficiency and reduce costs in urban settings. ↩

-

Explore this link to understand how major companies optimize deliveries using micro-hubs, enhancing efficiency in urban logistics. ↩